A Novel Approach to Dye Cotton Goods without Using Electrolyte

Abstract

Abstract Views: 0

Abstract Views: 0

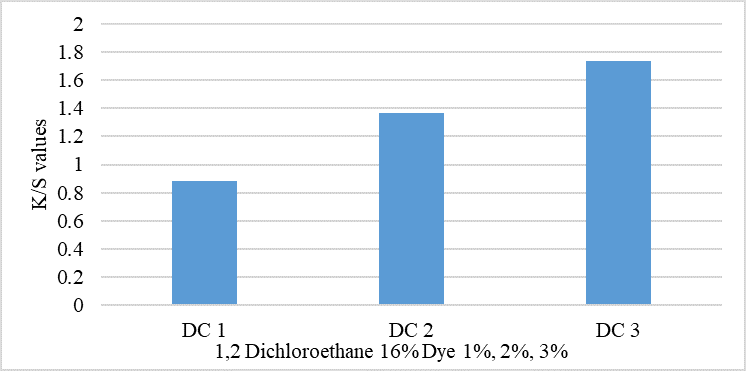

The current study centers on eliminating salt in the dyeing process of cotton products using reactive dyes. This study identified that the usage of reactive dyes is generating a huge amount of waste products that are contaminating the environment. Hence, this study introduces salt-free reactive dyes that can be used on cotton and would not contribute to ecological contamination. The prime purpose of this study was to explore a promising approach to reduce the cost of the dying process. Therefore, this study proposed the fiber modification technique based on chitosan and 1,2 dichloroethane as a proposed method for dying cotton, which will eventually help in reducing disposal and hazardous waste generated by salt-based chemicals. When the fabric is subjected to a treatment involving polyacrylamide, it causes cellulose to exhibit the main characteristics of wool. As a result, cotton can be dyed using reactive dyes under neutral pH conditions, without the need for electrolyte and alkali. Similarly, when fabric is treated with an emulsion of 1,2 dichloroethane followed by amination with sodium hydroxide, the treatment was discovered to enhance color fixation also. The modification was investigated through in-depth analysis in this research.

Downloads

References

L. S. NicDhuinnshleibhe, “A brief history of dyestuff and dyeing,” presented at the Runestone Collegium, 2000.

D. P. Chattopadhyay, “Cationization of cotton for low-salt or salt-free dyeing,” Ind. J. Fibre Text. Res., vol. 26, no. 1–2, pp. 108–115, 2001

M. C. Bonneau, “The chemistry of fabric reactive dyes,” J. Chem. Edu., vol. 72, no. 8. Art. no. 724, Aug. 1995, doi: https://doi.org/10.1021/ed072p724

A. Georgieva and D. Pishev, “Dyeing of cellulose textile material with reactive dyes,” Acad. J., vol. 53, no. 3, p. 65.

P. K. Dutta, J. Duta, and V. S. Tripathi, “Chitin and chitosan: Chemistry, properties and applications,” J. Sci. Ind. Res., vol. 63, no. 1, pp. 20–31, 2004

D. P. Chattopadhyay, R. B. Chavan, and J. K. Sharma, “Salt-free reactive dyeing of cotton,” Int. J. Cloth. Sci. Technol., vol. 19, no. 2, pp. 99–108, 2007, doi: https://doi.org/10.1108/09556220710725702

G. R. Gamble, “Cotton fiber chemical differences and their effect on frictionbehavior: A comparison of two crop years in the ATMI/ARS leading cultivars study,” J. Cotton Sci., vol. 64, pp. 56–64, 2005.

M. Kanik and P. J. Hauser, “Printing cationized cotton with direct dyes,” Text. Res. J., vol. 74, no. 1, pp. 43–50, 2004, doi: https://doi.org/10.1177/004051750407400108

E. Acuner and F. B. Dilek, “Treatment of tectilon yellow 2G by Chlorella vulgaris,” Process Biochem., vol. 39, no. 5, pp. 623–631, 2004, doi: https://doi.org/10.1016/S0032-9592(03)00138-9

L. Frazer, “A cleaner way to cotton,” Environ. Health Perspect., vol. 110, no. 5, pp. 252–254, 2002.

R. S. Blackburn and S. M. Burkinshaw, “Treatment of cellulose with cationic, nucleophilic polymers to enable reactive dyeing at neutral pH without electrolyte addition,” J. Appl. Polym. Sci., vol. 89, no. 4, pp. 1026–1031, May 2003, doi: https://doi.org/10.1002/app.12226

K. Smetana et al., “Effect of chemical structure of hydrogels on the adhesion and phenotypic characteristics of human monocytes such as expression of galectins and other carbohydrate-binding sites,” Biomaterials, vol. 18, no. 14, pp. 1009–1014, July 1997, doi: https://doi.org/10.1016/S0142-9612(97)00037-9

M. S. Kanana, M. Gobalakrishnan, S. Kumaravel, R. Nithyanandan, K. Rajashankar, and T. Vadicherala, “Influence of cationization of cotton on reactive dyeing,” J. Text. Apparel. Technol. Manag., vol. 5, no. 2, pp. 1–16, 2006.

A. El Shafie, M. M. G. Fouda, and M. Hashem, “One-step process for bio-scouring and peracetic acid bleaching of cotton fabric,” Carbohydr. Polym., vol. 78, no. 2, pp. 302–308, Sep. 2009, doi: https://doi.org/10.1016/j.carbpol.2009.04.002

J. Geis, “Colorfastness to crocking testing,” Manufacturing Solutions Center, 2017.

A. B. V. Kumar, M. C. Varadaraj, L. R. Gowda, and R. N. Tharanathan, “Characterization of chito-oligosaccharides prepared by chitosanolysis with the aid of papain and Pronase , and their bactericidal action against Bacillus cereus and Escherichia coli,” Biochem. J., vol. 391, no. 2, pp. 167–175, 2005, doi: https://doi.org/10.1042/BJ20050093

A. Percot, C. Viton, and A. Domard, “Optimization of chitin extraction from shrimp shells,” Biomacromolecules, vol. 4, no. 1, pp. 12–18, Nov. 2003, doi: https://doi.org/10.1021/bm025602k

R. Shepherd, S. Reader, and A. Falshaw, “Chitosan functional properties,” Glycoconj. J., vol. 14, no. 4, pp. 535–542, June 1997, doi: https://doi.org/10.1023/A:1018524207224

N. V. Toan, T. T. Hanh, and P. V. M. Thien, “Antibacterial activity of chitosan on some common food contaminating microbes,” Open Biomater. J., vol. 4, pp. 1–5, July 2013, doi: https://doi.org/10.2174/1876502501304010001

I. S. Arvanitoyannis, “Totally and partially biodegradable polymer blends based on natural and synthetic macromolecules: preparation, physical properties, and potential as food packaging materials,” J. Macromol. Sci. Part C Polym. Rev., vol. 39, no. 2, pp. 205–271, 1999, doi: https://doi.org/10.1081/MC-100101420

E. Karapinar and M. O. Sariisik, “Scouring of cotton with cellulases, pectinases and proteases,” Fibres Text. East. Eur., vol. 12, no. 3, pp. 79–82, 2004.

Asaduzzaman, M. R. Miah, F. Hossain, X. Li, Zakaria, and H. Quan, “A study on the effects of pre-treatment in dyeing Properties of Cotton Fabric and Impact on the Environment,” J. Text. Sci. Eng., vol. 6, no. 5, pp. 1–5, 2016.

N. Abdullah and F. Sulaiman, “The oil palm wastes in Malaysia,” in Biomass Now-Sustainable Growth and Use, M. D. Matovic, Ed., BoD - Books on Demand, 2013, pp. 75–93.

S. B. Abdul and G. Narendra, “Accelerated bleaching of cotton material with hydrogen peroxide - accelerated-bleaching-of-cotton-material-with-hydrogen-peroxide,” J. Text. Sci. Eng., vol. 3, no. 4, Art. no. 1000140, 2013.

M. Curry, “AATCC 147, Antibacterial activity assessment of textile materials,” Manufacturing Solutions Center, 2017.

American Association of Textile Chemists and Colorists, “Relative color strength of dyes in solution technically equivalent to ISO 105-Z10,” https://www.herculesebooks.com/index/AATCC.PDF (updated, 2011).

B. P. Saville, Physical testing of textiles. Woodhead Publishing, 1999.

M. A. R. Bhuiyan, A. Shaid, and M. A. Khan, “Cationization of cotton fiber by chitosan and its dyeing with reactive dye without salt,” Chem. Mater. Eng., vol. 2, no. 4, pp. 96–100, 2014, doi: https://doi.org/10.13189/cme.2014.020402

M. Sadeghi-Kiakhani and S. Safapour, “Salt-free reactive dyeing of the cotton fabric modified with chitosan-poly(propylene imine) dendrimer hybrid,” Fibers Polym., vol. 16, no. 5, pp. 1075–1081, June 2015, doi: https://doi.org/10.1007/s12221-015-1075-9

T. Oktem, “Surface treatment of cotton fabrics with chitosan,” Color. Technol., vol. 119, no. 4, pp. 241–246, July 2003, doi: https://doi.org/10.1111/j.1478-4408.2003.tb00179.x

R. C. Goy, S. T. B. Morais, and O. B. G. Assis, “Evaluation of the antimicrobial activity of chitosan and its quaternized derivative on E . coli and S . aureus growth,” Rev. Bras. Farmacogn., vol. 26, no. 1, pp. 122–127, 2016, doi: https://doi.org/10.1016/j.bjp.2015.09.010

C. I. Pearce, J. R. Lloyd, and J. T. Guthrie, “The removal of colour from textile wastewater using whole bacterial cells: A review,” Elsevier, vol. 58, no. 3, pp. 179–196, Sep. 2003, doi: https://doi.org/10.1016/S0143-7208(03)00064-0

S. A. S. Chatha et al., “Significance of chitosan to improve the substantivity of reactive dyes,” J. Chil. Chem., vol. 61, no. 2, pp. 2895–2897, June 2016, doi: http://dx.doi.org/10.4067/S0717-97072016000200009

M. Iftikhar, “Rubbing , ironing and dry cleaning fastness of reactive dyed cotton knitted fabric as influenced by salt , alkali and dye,” Int. J. Agric. Biol., vol. 3, pp. 109–112, 2001.

M. F. Shahin, “The Influence of cationization on the dyeing performance of cotton fabrics with direct dyes,” J. Eng. Res. Appl., vol. 5, no. 8, pp. 62–70, 2015.

Copyright (c) 2024 Faiza Anwar, Nadeem Afraz, Rehana Ijaz, Faisal Rehman, Wang Mei

This work is licensed under a Creative Commons Attribution 4.0 International License.

This work is licensed under a Creative Commons Attribution 4.0 International License. Authors retain copyright and grant the journal right of first publication with the work simultaneously licensed under a Creative Commons Attribution (CC-BY) 4.0 License that allows others to share the work with an acknowledgement of the work’s authorship and initial publication in this journal.