Characterization and Optimization Techniques for the Extraction of Fibers from Ficus Thonningii

Abstract

Abstract Views: 0

Abstract Views: 0

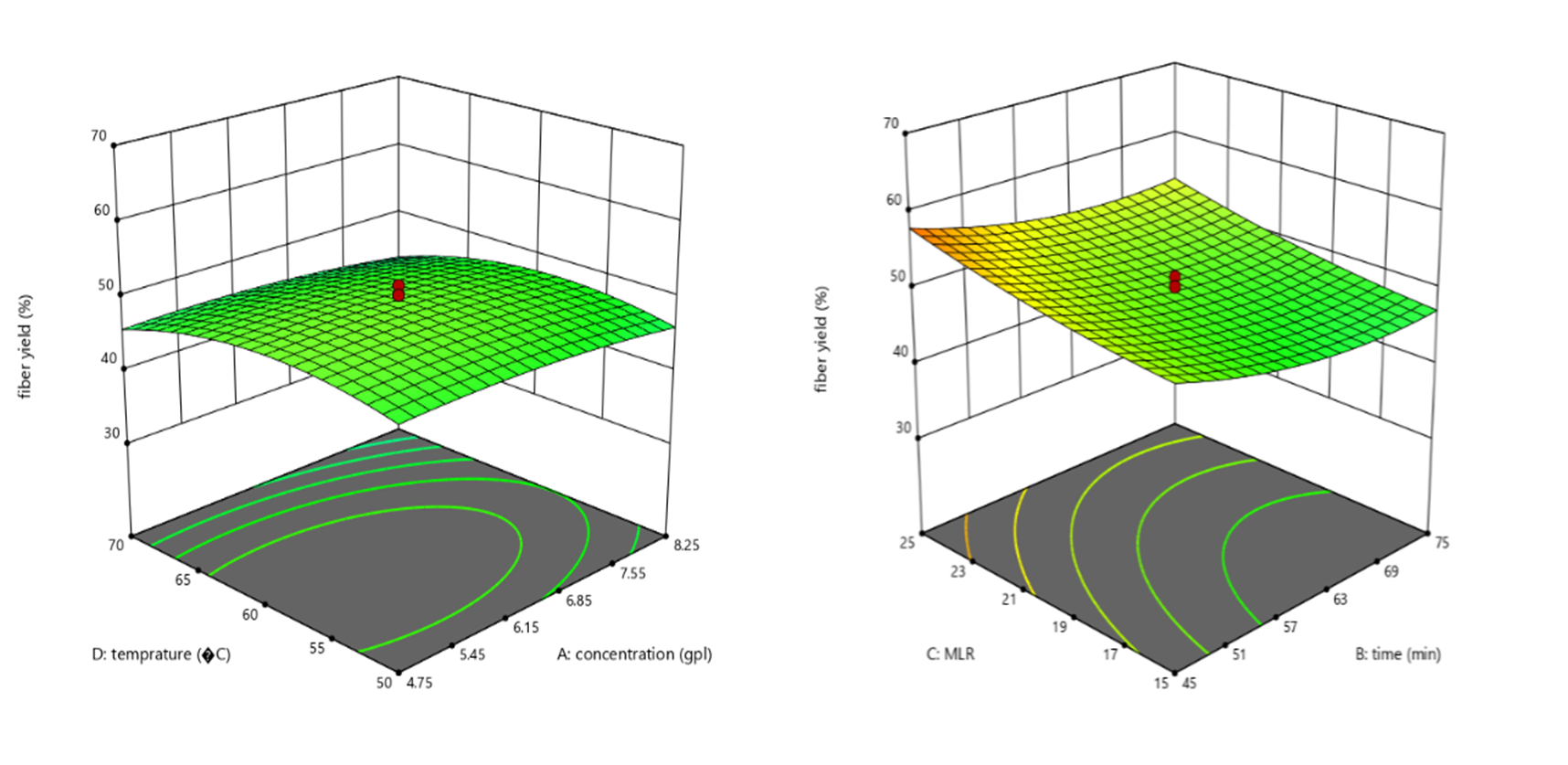

The investigation of natural fibers as viable substitutes for synthetic materials has intensified due to environmental and financial considerations. It has been acknowledged that Ficus thonningii is a viable source of natural fibers due to its resistance and capabilities. The current study aimed to extract and characterize F. thonningii fibers from F. thonningii plant found in Ethiopia. The extraction methods used included water and chemical retting with sodium hydroxide. The extraction was optimized by DOE. Mechanical, physical, and chemical properties of the extracted fibers, such as tensile strength, elongation, fiber length and diameter, fiber fineness, moisture content, moisture regain, fiber’s cellulose, hemicellulose, lignin, and ash contents were characterized. Results showed that F. thonningii fibers have comparable fiber strength (39.65cN by chemical extraction and 37.83cN by water extraction), elongation (3.02% by water extraction and 2.6% by chemical extraction), fiber length (101.5mm by both methods), moisture content (10.35% by water extraction and 10.78% by chemical extraction), and moisture regain (11.02% by water extraction and 11.98% by chemical extraction) with jute, sisal, and flax. The chemical composition was found to be 52.35% of cellulose, 19.2% of hemicellulose, 17.2% of lignin, and 1.2% of ash for water extraction and 63.57% of cellulose, 16.1% of hemicellulose, 12.1% of lignin, and 0.83% of ash for chemical extraction. This proves that F. thonningii plant found in Ethiopia is a source of coarse fibers, thus, can be utilized for technical textiles application.

Downloads

References

R. Prasad and E. Aranda, Eds. Approaches in Bioremediation: The New Era of Environmental Microbiology and Nanobiotechnology. Springer, 2018.

A. M. Manich, P. N. Marino, M. D. de Castellar, M. Saldivia, and R. M. Sauri, “Viscoelastic modeling of natural and synthetic,” J. Appl. Polym. Sci., vol. 76, pp. 2062–2067, June 2000, doi: https://doi.org/10.1002/(SICI)1097-4628(20000628)76:14%3C2062::AID-APP9%3E3.0.CO;2-T.

M. Prithiviraj, R. Muralikannan, P. Senthamaraikannan, and S. S. Saravanakumar, “Characterization of new natural cellulosic fiber from the Perotis indica plant,” Int. J. Polym. Anal. Charact., vol. 21, no. 8, pp. 669–674, 2016, doi: https://doi.org/10.1080/1023666X.2016.1202466.

S. F. Oyelere et al., “Phytochemical analysis of Ficus thonningii: A qualitative study,” J. Med. Herbs Ethnomed., vol. 7, pp. 47–51, July 2021, doi: https://doi.org/10.25081/jmhe.2021.v7.7109.

R. Dangarembizi, K. H. Erlwanger, D. Moyo, and E. Chivandi, “Phytochemistry, pharmacology and ethnomedicinal uses of Ficus thonningii (Blume Moraceae): a review,” Afr. J. Tradit. Complement. Altern. Med., vol. 10, no. 2, pp. 203–212, Jan. 2013, doi: https://doi.org/10.4314/ajtcam.v10i2.4.

E. T. Fokunang et al., “Phytochemical screening and in vivo evaluation of antiulcer properties of secondary metabolites in aqueous extracts of Ficus. thonningii Blume tested on Wistar rats,” Int. J. Biol. Chem. Sci., vol. 13, no. 1, pp. 475–492, May 2019, doi: https://doi.org/10.4314/ijbcs.v13i1.38.

E. Taban et al., “Morphological, acoustical, mechanical and thermal properties of sustainable green Yucca (Y. gloriosa) fibers: An exploratory investigation,” J. Environ. Heal. Sci. Eng., vol. 18, no. 2, pp. 883–896, July 2020, doi: https://doi.org/10.1007/s40201-020-00513-9.

M. O. Falade et al., “In vitro and in vivo antimalarial activity of ficus thonningii blume (Moraceae) and lophira alata banks (Ochnaceae), identified from the ethnomedicine of the nigerian middle belt,” J. Parasitol. Res., vol. 2014, 2014, doi: https://doi.org/10.1155/2014/972853.

R. Dangarembizi, K. H. Erlwanger, D. Moyo, and E. Chivandi, “Phytochemistry , pharmacology and ethnomedicinal uses of ficus thonningII ( Blume Moraceae ): A review,” Afr. J. Tradit. Complement. Altern. Med., vol. 10, no. 2, pp. 203–212, Jan. 2013, doi: https://doi.org/10.4314/ajtcam.v10i2.4.

A. Usman, F. I. Abdulrahman, and A. Usman, “Qualitative phytochemical screening and in vitro antimicrobial effects of methanol stem bark extract of Ficus thonningii (Moraceae),” Afr. J. Tradit. Complement. Altern. Med., vol. 6, no. 3, pp. 289–295, 2009, doi: https://doi.org/10.4314/ajtcam.v6i3.57178.

B. Asmare and Y. Mekuriaw, “Assessment of ficus thonningii tree production and utilization for livestock feed by smallholder farmers in northwestern Ethiopia,” Agric. Food Secur., vol. 8, no. 1, Art. no. 8, Jan. 2019, doi: https://doi.org/10.1186/s40066-018-0247-4.

M. Hasan, M. Rahman, Y. Chen, and N. Cicek, “Optimization of typha fibre extraction and properties for bio-composite applications using desirability function analysis,” Polymers, vol. 14, no. 9, Art. no. 1685, 2022, doi: https://doi.org/10.3390/polym14091685.

T. Radhakrishnan, P. Neelakantan, and T. Narasimham, “Airflow through fiber plugs,” Text. Res. J., vol. 61, no. 7, pp. 382–385, July 1991, doi: https://doi.org/10.1177/004051759106100703.

G. N. Onyeagoro, “Effect of chemical treatment on the constituents and tensile properties of oil palm leaf fibre,” Acad. Res. Int., vol. 2, no. 3, pp. 88–98, 2012.

D. Atalie and R. K. Gideon, “Extraction and characterization of Ethiopian palm leaf fibers,” Res. J. Text. Appar., vol. 22, no. 1, pp. 15–25, Mar. 2018, doi: https://doi.org/10.1108/RJTA-06-2017-0035.

Z. Daud, H. Awang, A. S. M. Kassim, M. Z. M. Hatta, and A. M. Aripin, “Comparison of pineapple leaf and cassava peel by chemical properties and morphology characterization,” Adv. Mater. Res., vol. 974, pp. 384–388, 2014, doi: https://doi.org/10.4028/www.scientific.net/AMR.974.384.

C. L. Gomes, E. Gonçalves, C. A. G. Suarez, D. de Sousa Rodrigues, and I. C. Montano, “Effect of reaction time and sodium hydroxide concentration on delignification and enzymatic hydrolysis of brewer’s spent grain from two brazilian brewers,” Cellul. Chem. Technol., vol. 55, no. 1–2, pp. 101–112, 2021, doi: https://doi.org/10.35812/CelluloseChemTechnol.2021.55.10.

L. Tan, Y. Q. Tang, H. Nishimura, S. Takei, S. Morimura, and K. Kida, “Efficient production of bioethanol from corn stover by pretreatment with a combination of sulfuric acid and sodium hydroxide,” Prep. Biochem. Biotechnol., vol. 43, no. 7, pp. 682–695, June 2013, doi: https://doi.org/10.1080/10826068.2013.773338.

A. A. Modenbach and S. Nokes, “Effects of sodium hydroxide pretreatment on structural components of biomass,” Trans. ASABE, vol. 57, pp. 1187–1198, Sep. 2014, doi: https://doi.org/10.13031/trans.57.10046.

A. Lotfi, H. Li, D. V. Dao, and G. Prusty, “Natural fiber–reinforced composites: A review on material, manufacturing, and machinability,” J. Thermoplast. Compos. Mater., vol. 34, no. 2, pp. 238–284, 2021, doi: https://doi.org/10.1177/0892705719844546.

M. M. Thrasybule, “Differentiated cntent: An expose on ceiba pentandra and ficus thonningii species as perceived in the haitian beliefs,” Saudi J. Humanit. Soc. Sci., vol. 7, no. 8, pp. 380–397, Aug. 2022, doi: https://doi.org/10.36348/sjhss.2022.v07i08.006.

B. S. Kaith, H. Mittal, R. Jindal, M. Maiti, and S. Kali, “Cellulose fibers: Bio- and nano-polymer composites,” in Cellulose Fibers: Bio-And Nano-Polymer Composites: Green Chemistry and Technology, S. Kalia, B. S. Kaith and I. Kaur, Eds. Springer, 2015, pp. 425–452.

Copyright (c) 2024 Yohannes Shitahun, Simegn Adane, Terefe Aferu, Kalkidan Tadesse, Biruk Fentahun, Endalkachew Debebe

This work is licensed under a Creative Commons Attribution 4.0 International License.

This work is licensed under a Creative Commons Attribution 4.0 International License. Authors retain copyright and grant the journal right of first publication with the work simultaneously licensed under a Creative Commons Attribution (CC-BY) 4.0 License that allows others to share the work with an acknowledgement of the work’s authorship and initial publication in this journal.