Development of Green/Skin-friendly Textiles by Minimizing Formaldehyde Content in Pigment Printing

Abstract

Abstract Views: 0

Abstract Views: 0

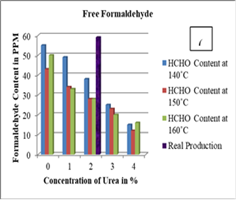

This study aims to reduce the content of formaldehyde in pigment printed cotton fabric with deep shades. A hand screen printing method was applied using various curing temperatures and concentrations of urea for preparation of skin-friendly products. The woven, bleached fabrics were printed following a precise process of screen printing and these samples were dried and curried for proper fixation. Standard test procedures were followed to assess the content of H-CHO (formaldehyde) during washing and rubbing. H-CHO contents were instantly reduced by increasing the temperature of the printed fabric during curing. The best outcome for wet and dry fastness of rubbing was achieved at 160˚C, while a little enhanced rubbing outcomes were observed when the concentration of urea was 2% at a fixation temperature of 150˚C. The final product may be effectively used for clothing purpose, meeting the OEKO-TEX® Standard 100 standard for low formaldehyde content.

Downloads

References

W. Schwindt and G. Faulhaber, “The development of pigment printing over the last 50 years,” Rev. Prog. Coloration Relat. Topics, vol. 14, no. 1, pp. 166–175, June 1984, doi: https://doi.org/10.1111/j.1478-4408.1984.tb00058.x.

M. M. El-Molla, H. S. El-Sayad, M. A. El-Kashouti, and R. S. El-Khawaga, “Use of the newly synthesized aqueous polyurethane acrylate binders for printing cotton and polyester fabrics,” Adv. Chem. Eng. Sci., vol. 2, no, Art. no. 18895, 2012, doi: https://doi.org/10.4236/aces.2012.22027.

M. M. El-Molla, K. Haggag, N. Fatma, and N. Shaker, “Part 1: Synthesis and evaluation of novel nano scale powdered polyurethane acrylate binders,” Adv. Chem. Eng. Sci., vol. 2, no, Art. no. 18893, 2012, doi: https://doi.org/10.4236/aces.2012.22026.

A. Hu, H. Peng, M. Li, and S. Fu, “Preparation of melamine‐formaldehyde encapsulated fluorescent dye dispersion and its application to cotton fabric printing,” Coloration Technol., vol. 135, no. 2, pp. 103–110, 2019, doi: https://doi.org/10.1111/cote.12379.

M. El-Molla and R. Schneider, “Development of ecofriendly binders for pigment printing of all types of textile fabrics,” Dyes Pigments, vol. 71, no. 2, pp. 130–137, 2006, doi: https://doi.org/10.1016/j.dyepig.2005.06.017.

H. Wang, “An ultra-low free-formaldehyde durable flame-retarding finishing for ramie fabric,” J. Nat. Fibers, vol. 16, no. 4, pp. 545–554, 2019, doi: https://doi.org/10.1080/15440478.2018.1428845.

A. K. Patra and S. R. K. Pariti, “Restricted substances for textiles,” Text. Prog., vol. 54, no. 1, pp. 1–101, 2022, doi: https://doi.org/10.1080/00405167.2022.2101302.

L. Berrens, E. Young, and L. Jansen, “Free formaldehyde in textiles in relation to formalin contact sensitivity,” J. Occup. Environ. Med., vol. 6, no. 10, Art. no. 424, 1964.

R. M. Novick, M. L. Nelson, M. A. McKinley, G. L. Anderson, and J. J. Keenan, “The effect of clothing care activities on textile formaldehyde content,” J. Toxicol. Environ. Health, vol. 76, no. 14, pp. 883–893, Sep. 2013, doi: https://doi.org/10.1080/15287394.2013.821439.

M. Herrero et al., “Early-life exposure to formaldehyde through clothing,” Toxics, vol. 10, no. 7, Art. no. 361, June 2022, doi: https://doi.org/10.3390/toxics10070361.

Y. Kawakami, Y. Y. Maruo, T. Nakagawa, and H. Saito, “A screening method for detecting formaldehyde emitted from textile products,” Measurement, vol. 62, pp. 41–46, Feb. 2015, doi: https://doi.org/10.1016/j.measurement.2014.11.005.

N. Aldag, J. Gunschera, and T. Salthammer, “Release and absorption of formaldehyde by textiles,” Cellulose, vol. 24, pp. 4509–4518, 2017, doi: https://doi.org/10.1007/s10570-017-1393-8.

P.-A. Bourgeois et al., “Characterization of a new photocatalytic textile for formaldehyde removal from indoor air,” Appl. Catal. B: Environ., vol. 128, pp. 171–178, Nov. 2012, doi: https://doi.org/10.1016/j.apcatb.2012.03.033.

M. Krzyzanowski, J. J. Quackenboss, and M. D. Lebowitz, “Chronic respiratory effects of indoor formaldehyde exposure,” Environ. Res., vol. 52, no. 2, pp. 117–125, Aug. 1990, doi: https://doi.org/10.1016/S0013-9351(05)80247-6.

X. Tang et al., “Formaldehyde in China: production, consumption, exposure levels, and health effects,” Environ. Int., vol. 35, no. 8, pp. 1210–1224, Nov. 2009, doi: https://doi.org/10.1016/j.envint.2009.06.002.

A. Songur, O. A. Ozen, and M. Sarsilmaz, “The toxic effects of formaldehyde on the nervous system,” in Reviews of Environmental Contamination and Toxicology, David M. Whitacre, Ed., Springer, 2010, pp. 105–118.

D. S. Brookstein, “Factors associated with textile pattern dermatitis caused by contact allergy to dyes, finishes, foams, and preservatives,” Dermatol. Clin., vol. 27, no. 3, pp. 309–322, July 2009, doi: https://doi.org/10.1016/j.det.2009.05.001.

T. Gulzar, T. Farooq, S. Kiran, I. Ahmad, and A. Hameed, “Green chemistry in the wet processing of textiles,” in The Impact and Prospects of Green Chemistry for Textile Technology, Shahid-ul-Islam & B.S. Butola, Eds., Elsevier, 2019, pp. 1–20.

Y. Okada, A. Sugane, F. Fukuoka, and Z. Morita, “An assessment of testing methods of color fastness to light, water and perspiration, and related methods with some reactive dyes,” Dyes Pigments, vol. 39, no. 1, pp. 1–23, July 1998, doi: https://doi.org/10.1016/S0143-7208(97)00068-5.

M. Zaeem and A. Chatha, “Investigation of low formaldehyde easy-care textile finishes on dyed cotton fabric,” J. Chem. Soc. Pak., vol. 41, no. 6, pp. 975–982, 2019.

T. Toprak and P. Anis, “Textile industry’s environmental effects and approaching cleaner production and sustainability, an overview,” J. Text. Eng. Fashion Technol., vol. 2, no. 4, pp. 429–442, 2017.

M. Abdelrahman, S. Wahab, H. Mashaly, D. Maamoun, and T. A. Khattab, “Review in textile printing technology,” Egypt. J. Chem., vol. 63, no. 9, pp. 3465–3479, 2020, doi: https://dx.doi.org/10.21608/ejchem.2020.23726.2418.

M. N. Karim, M. Rigout, S. G. Yeates, and C. Carr, “Surface chemical analysis of the effect of curing conditions on the properties of thermally-cured pigment printed poly (lactic acid) fabrics,” Dyes Pigments, vol. 103, pp. 168–174, Apr. 2014, doi: https://doi.org/10.1016/j.dyepig.2013.12.010.

A. Dessie and B. Eshetu, “The role of binders and its chemistry in textile pigment printing,” J. Text. Sci. Eng., vol. 11, no. 1, pp. 1–6, 2021.

Q. Cao, “An investigation into the development of environmentally friendly pigment colouration,” Ph.D. dissertation, The Univ. Manchester, United Kingdom, 2013.

Copyright (c) 2025 Muhammad Irfan Siyal, Sidra Saleemi, Noorullah Soomro, Raja Fahad Qureshi

This work is licensed under a Creative Commons Attribution 4.0 International License.

This work is licensed under a Creative Commons Attribution 4.0 International License. Authors retain copyright and grant the journal right of first publication with the work simultaneously licensed under a Creative Commons Attribution (CC-BY) 4.0 License that allows others to share the work with an acknowledgement of the work’s authorship and initial publication in this journal.