Anti-Pilling Properties of Polyester-Cotton Blend using Plasma and Chemical Finish

Abstract

Abstract Views: 0

Abstract Views: 0

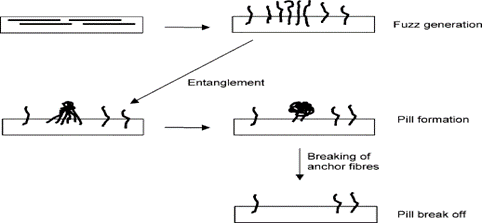

Plasma treatment is an effective, efficient, and environment- friendly technology which is currently being used to modify the surface of textile substrate and its chemical structure. However, limited research has been conducted regarding the influence of plasma technology on the characteristics of blends. This project throws light on the effect of plasma treatment on the pilling properties of polyester-cotton blends. In cold plasma, different reactive species interact with substrate surface. The cleaning, modification, and coating processes are dependent upon the parameters (e.g., plasma source and imput voltage). There are three main mechanisms involved in plasma treatment, that is, radical formation, attachment of functional groups, deposition/polymerization, and the etching process. Maximum resistance to pill formation may be achieved using the plasma treatment on the p/c blend.

Downloads

References

Punjab Board of Investment and Trade, “Textile sector of Pakistan: Analysis by projects & policy research department,” 2018. [Online]. Available: https://pbit.gop.pk/system/files?file=Textile%20Industry_0.pdf

WWF-Pakistan. “Collective action in the Indus River basin, Pakistan.” https://wwf.panda.org/discover/our_focus/freshwater_practice/water_stewardship/our_sectors/key_performance_indicators/collective_action_pakistan/ (accessed Jan. 7, 2024).

M. Khan. “Strategic analysis of Pakistan textile industry - Successes, failures in the last thirty years.” 2019. Academia. https://www.academia.edu/10119275/Strategic_Analysis_of_Pakistan_Textile_Industry__Successes_Failures_in_the_last_thirty_years (accessed Jan. 7. 2024).

D. Gintis and E. J. Mead, “The mechanism of pilling,” Text. Res. J., vol. 29, no. 9, pp. 578–585, July 1959, doi: https://doi.org/10.1177/004051755902900709.

W. Conti and E. Tassinari, “14—A simplified kinetic model for the mechanism of pilling,” J. Text. Instit., vol. 65, no. 3, pp. 119–125, 1974, doi: https://doi.org/10.1080/00405007408630358.

W. Schindler and J. P. Hauser, “Anti-pilling finishes,” Semantic Scholar, Art. no. 135959596, 2004, doi: https://doi.org/10.1533/9781845690373.129.

S. Sosnowski, L. Li, M. A. Winnik, B. Clubb, and R. Shivers, “Morphology of melt‐pressed latex films examined by scanning and freeze‐fracture electron microscopy,” J. Polym. Sci. Polym. Phy., vol. 32, no. 15, pp. 2499–2508, Nov. 1994, doi: https://doi.org/10.1002/polb.1994.090321507.

H. Petersen and N. Petri, “Apparatus and description of the procedure for determining the formaldehyde emitted during curing of nonwoven binders,” Mell. Textilb.,” vol. 66, no. 4, pp. 285–295, 1985.

S. E. Braddock and M. O'Mahony, Techno Textiles: Revolutionary Fabrics for Fashion and Design. Thames and Hudson, 1999.

K. Reichel, “Plasma treatment, process diversity and sustainability,” German Federal Ministry of Education and Research, 2001.

C. Tomasino, J. J. Cuomo, C. B. Smith, and G. Oehrlein, “Plasma treatments of textiles,” J. Coated Fab., vol. 25, no. 2, pp. 115–127, Oct. 1995, doi: https://doi.org/10.1177/152808379502500204

K. El-Nagar, M. A. Saudy, A. I. Eatah, and M. M. Masoud, “DC pseudo plasma discharge treatment of polyester textile surface for disperse dyeing,” J. Text. Instit., vol. 97, p. 111–117, July 2006, doi: https://doi.org/10.1533/joti.2005.0169.

R. Shishoo, Plasma Technologies For Textiles. Woodhead Publishing, 2007.

J. G. A. Terlingen, “Introduction of functional groups at polymer surfaces by Glow discharge techniques,” Doctoral dissertation, Uni. Twente, 1993. [Online]. Available: https://research.utwente.nl/en/publications/introduction-of-functional-groups-at-polymer-surfaces-by-glow-dis

M. Sotton and G. Nemoz, “New surface treatments and new fibers: The challenge to satisfy new requirements for technical textiles,” J. Indust. Text., vol. 24, no. 2, pp. 138–151, Oct. 1994, doi: https://doi.org/10.1177/152808379402400206.

Diener Electronics. “Plasma surface technology.” https://www.plasma.com/uploads/media/Imagebroschuere_EN.pdf (accessed Jan. 7, 2024).

J. Yip, K. Chan, K. M. Sin, and K. S. Lau, “Low temperature plasma-treated nylon fabrics,” J. Mater. Proc. Technol., vol. 123, no. 1, pp. 5–12, Apr. 2002, doi: https://doi.org/10.1016/S0924-0136(02)00024-9.

H. A. Karahan, E. Özdoğan, A. Demir, H. Aydin, and N. Seventekin, “Effects of atmospheric pressure plasma treatments on certain properties of cotton fabrics,” Fib. Text. East. Eur., vol. 2, no. 73, pp. 19–22, 2009.

M. R. Wertheimer, L. Martinu, J. E. Klembert-Sapieha, and G. Czeremuszkin. Adhesion Promotion Techniques. Marcel Dekker Inc, 1999.

K. Kale, S. Palaskar, P. J. Hauser, and A El-Shafei, “Atmospheric pressure glow discharge of helium-oxygen plasma treatment on polyester-cotton blend fabric,” Ind. J. Fibre Text. Res., vol. 36, pp. 137–144, June 2011.

Y.-H. Ryu et al., “Effects of background fluid on the efficiency of inactivating yeast with non-thermal atmospheric pressure plasma,” PLoS ONE, vol. 8, no. 6, Art. no. 66231, 2013, doi: https://doi.org/10.1371/journal.pone.0066231.

A. Wan, X. J. Dai, K. Magniez, J. du Plessis, W. Yu, X. Wang, “Reducing the pilling propensity of wool knits with a three-step plasma treatment,” Text. Res. J., vol. 83, no. 19, pp. 2051–2059, Mar. 2013, doi: https://doi.org/10.1177/0040517513478459.

Z. Wang and J. Shao, “Application of sol-gel technology in anti-pilling finishing of wool fabrics,” in China Inter. Wool Text. Conf. IWTO Wool Forum, China, 2006, pp. 493–498.

J. R. Ghonia, N. G. Savani, V. Prajapati, and B. Z. Dholakiya, “A review on polyurethane based multifunctional materials synthesis for advancement in textile coating applications,” J. Polym. Res., vol. 31, no. 3, Art. no. 95, Mar. 2024, doi: https://doi.org/10.1007/s10965-024-03941-5.

H. Quan, J. Wu, Q. Sun, J. Chen, and Z. Wei, “Anti-pilling and anti-static bifunctional finishing of cashmere knitted fabric based on combinatorial foaming microcoating of anionic hydrophilic polyurethane,” Text. Res. J., vol. 93, no. 7–8, pp. 1851–1860, Apr. 2023, doi: https://doi.org/10.1177/00405175221130523.

K. T. Rashid, N. Akram, K. M. Zia, M. Usman, and T. Munawar, “Novel enrichment in biobased monomers of waterborne polyurethane dispersions as a textile finishing agent for poly-cotton fabrics,” Int. J. Biol. Macromol., vol. 257, Art. no. 128674, Feb. 2024, doi: https://doi.org/10.1016/j.ijbiomac.2023.128674.

H. Othman et al., “Various printing techniques of viscose/polyester fabric to enhancing its performance properties,” J. Text. Color. Polym. Sci., vol. 20, no. 2, pp. 285–295, Sep. 2023, doi: https://dx.doi.org/10.21608/jtcps.2023.220581.1198.

H. Bao, Y. Hong, T. Yan, X. Xie, and X. Zeng, “A systematic review of biodegradable materials in the textile and apparel industry,” J. Text. Inst., vol. 115, no. 7, pp. 1173–1192, July, 2024, doi: https://doi.org/10.1080/00405000.2023.2212848.

Y. Yang et al., “Poly(lactic acid) fibers, yarns and fabrics: Manufacturing, properties and applications,” Text. Res. J., vol. 91, no. 13–14, pp. 1641–1669, July 2021, doi: https://doi.org/10.1177/0040517520984101.

A. Wan and W. Yu, “Effect of wool fiber modified by ecologically acceptable ozone-assisted treatment on the pilling of knit fabrics,” Text. Res. J., vol. 82, no. 1, pp. 27–36, Jan. 2012, doi: https://doi.org/10.1177/0040517511414973.

H. N. S. Yadav and M. Das, “Design and development of medium-pressure plasma process for optical substrate finishing: A comparative study with wet chemical etching,” J. Manuf. Process., vol. 109, pp. 628–642, Jan. 2024, doi: https://doi.org/10.1016/j.jmapro.2023.12.034.

M. Rahman, J. Profili, L. Stafford, and C. Moreau, “Surface preparation of aluminum by atmospheric-pressure plasma jet for suspension plasma sprayed ceramic coatings,” Surf. Coat. Technol., vol. 476, Art. no. 130175, Jan. 2024, doi: https://doi.org/10.1016/j.surfcoat.2023.130175.

H. N. S. Yadav, M. Kumar, A. Kumar, and M. Das, “Plasma polishing processes applied on optical materials: A review,” J. Micromanufact, vol. 6, no. 1, pp. 27–39, May 2023, doi: https://doi.org/10.1177/25165984211038882.

Copyright (c) 2024 Adil Hussain, Reamsha Khan

This work is licensed under a Creative Commons Attribution 4.0 International License.

This work is licensed under a Creative Commons Attribution 4.0 International License. Authors retain copyright and grant the journal right of first publication with the work simultaneously licensed under a Creative Commons Attribution (CC-BY) 4.0 License that allows others to share the work with an acknowledgement of the work’s authorship and initial publication in this journal.