Improvement of Sigma level in a Finishing Department of Home Textile Unit Industry

Abstract

Abstract Views: 0

Abstract Views: 0

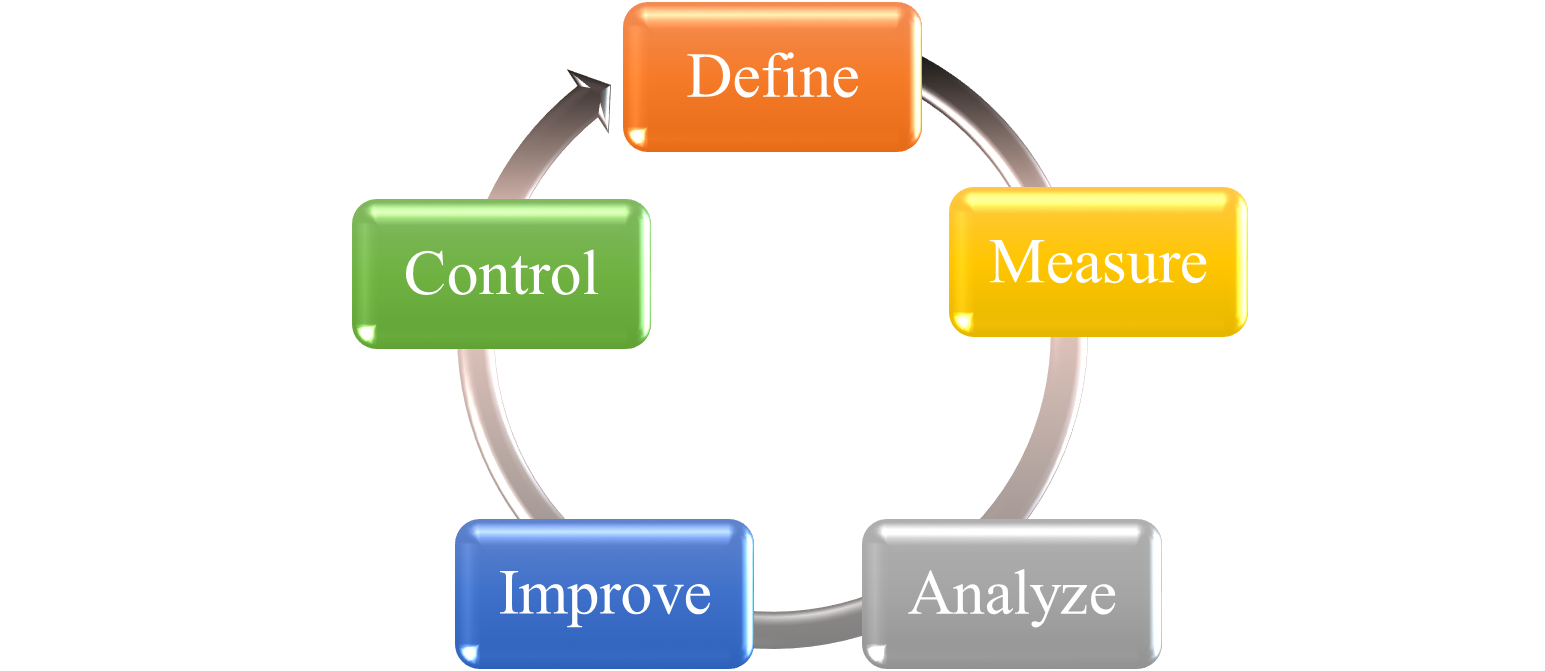

The research is done on the finishing department of home textile unit, the purpose is to reduce the defects which were encountering during the finishing process, 3M is used in which man, machine and material are included has been reviewed and Root cause Analysis is done to archive better sigma level. Finishing department is serving for bleach, dyed & printed fabric, more chances of defects to be rise in Finishing side as for dying & printing, the fabric is repeated twice or thrice depending upon the print or dyed quality and parameters requirement, the sigma level before improvement was 3.31, after successful implementation of improvement and defects minimization sigma level of Finishing department was improved to 3.71 (13500 Defects per day). Thus, with the of Six sigma tools the production losses would take into control and significant amount of labor cost, time and utilities (Steam, compressed air, water and Power) would also take into control.

Downloads

References

G. Kolhe, V. Upadhayay, and Y. Ladhe, “A study on implementation of Six Sigma process in industry,” Int. J. Adv. Res. Ideas Innov. Technol., vol. 3, no. 8, Art. no. V3I8–1168, 2018.

P. Jirasukprasert, J. A. Garza-Reyes, V. Kumar, and M. K. Lim, “A Six Sigma and DMAIC application for the reduction of defects in a rubber gloves manufacturing process,” Int. J. Lean Six Sigma, vol. 5, no. 1, pp. 2–22, Feb. 2014, doi: https://doi.org/10.1108/IJLSS-03-2013-0020.

T. M. Ibrahim, “Implementation of Lean Six Sigma in the yarn manufacturing: A case study,” J. Text. Apparel Technol. Manag., vol. 10, no. 12, pp. 1703–1715, Dec. 2019.

M. Zaman, S. K. Pattanayak, and A. C. Paul, “Study of feasibility of Six Sigma implementation in a manufacturing industry: A case study,” Int. J. Res. Eng. Technol., vol. 3, no. 1, pp. 96–100, 2017.

Asaduzzaman, M. Mir, F. Hossain, X. Li, Zakaria, and H. Quan, “A study on the effects of pre-treatment in dyeing properties of cotton fabric and impact on the environment,” J. Text. Sci. Eng., vol. 6, no. 5, 2020, Article e5, doi: https://doi.org/10.4172/2165-8064.1000274.

A. R. Natarajan and S. Kumar, “Revolutionizing textile dyeing: Investigating water-saving strategies from a research perspective,” Int. J. Creat. Res. Thoughts, vol. 12, no. 7, pp. b239–b245, 2020.

J. Lavanya and N. Kishore, “Different textile printing techniques: Hand block printing, screen printing, and digital printing,” J. Text. Sci. Eng., vol. 19, no. 2, pp. 787–802, 2022.

G. Anand and A. M. Pramanik, “An introduction to sustainable finishing techniques of textiles,” Int. J. Home Sci., vol. 8, no. 2, pp. 217–220, 2020.

K. Thomas et al., “Fundamental challenges and opportunities for textile circularity,” Sustainability, vol. 16, no. 24, 2024, Art. no. 11117.

F. Murmura et al., “Lean Six Sigma for the improvement of company processes: The Schnell S.p.A. case study,” TQM J., vol. 33, no. 7, pp. 351–376, 2018, doi: https://doi.org/10.1108/TQM-06-2021-0196.

A. Ali et al., "Hydrophobic treatment of natural fibers and their composites—A review," J. Indus. Text., vol. 47, no. 8, pp. 2153–2183, June 2016, doi: https://doi.org/10.1177/1528083716654468.

M. Tarai and S. Yadav, "Advances in textile finishing," Int. J. Res. Trends Inn., vol. 9, no. 4, pp. 26–32, 2020.

S. Parmar and T. Malik. Home textiles: A review. (2020). [Online]. Available: https://www.researchgate.net/publication/326508042_Home_Textiles-A_Review_Home_Textiles-A_Review

R. Baloyi et al., "Recent advances in recycling technologies for waste textile fabrics: A review," Text. Res. J., vol. 94, no. 3, pp. 508–529, Nov. 2023, doi: https://doi.org/10.1177/00405175231210239.

T. Ahmed et al., "Implementation of the Six Sigma methodology for reducing fabric defects on the knitting production floor: A sustainable approach for knitting industry," Text. Leather Rev., vol. 5, pp. 223–239, 2023, doi: https://doi.org/10.31881/TLR.2022.29.

C. J. Moin, K. R. Hossain, and L. M. Baral, "Investigating root causes of sewing defects using TQM tools for quality improvement in the knit garment industry," Text. Leather Rev., vol. 6, pp. 417–433, Sep. 2023, doi: https://doi.org/10.31881/TLR.2023.071.

R. L. Karwande, S. P. Bhosle, and P. M. Ambad, "A review of Six Sigma approach to enhance performance in manufacturing industries," in Proc. Int. Conf. Appl. Mach. Intell. Data Anal., Aurangabad, India, 2017, pp. 654–663.

R. Sekhar, S. Shaikh, I. Akbani, and N. S. Solke, “Pareto analysis-based investigation and reduction of welding-defects in automobile ring gear/flex plate assembly,” Int. J. Appl. Eng. Res., vol. 10, no. 4, pp. 9811–9818, 2015.

H. Z. Ozek and D. Y. Ayakta, "TPM project for remedying weft distortions in a textile mill," J. Text. Sci. Technol., vol. 11, no. 1, pp. 6–13, 2019, doi: https://doi.org/10.15406/jteft.2025.11.00397.

T. Islam and M. A. Halim, "Washing defects and remedial actions of denim garments and statistical review of denim sectors in emerging economy," J. Manag. Sci. Eng. Res., vol. 4, no.1, pp. 30–40, 2020, doi: https://doi.org/10.30564/jmser.v4i1.2941.

R. D. Adikorley, L. Rothenberg, and A. Guillory, "Lean Six Sigma applications in the textile industry: A case study," Int. J. Lean Six Sigma, vol. 8, no. 2, pp. 210–224, 2017, doi: http://dx.doi.org/10.1108/IJLSS-03-2016-0014.

G. Jiménez-Delgado et al., "Implementation of Lean Six Sigma to improve the quality and productivity in the textile sector: A case study," Presented at 14th Int. Conf., Held Part 25th HCI Int. Conf., Copenhagen, Denmark, July 23–28, 2023.

S. Tampubolon and H. H. Purba, “Lean Six Sigma implementation, a systematic literature review,” Int. J. Product. Manag. Eng., vol. 9, no. 2, pp. 125–139, July 2021, doi: http://dx.doi.org/10.4995/ijpme.2021.14561.

T. A. V. Nguyen, K. H. Nguyen, and D. Tucek, "Total quality management 4.0 framework: Present and future," Oper. Supply Chain Manag., vol. 16, no. 3, pp. 311–322, 2023.

A. Susmita, "A systematic literature review of Total Quality Management (TQM) implementation in organization," Indones. J. Indust. Eng. Manag., vol. 2, no. 1, pp. 68–80, Feb. 2021. doi: https://doi.org/10.22441/ijiem.v2i1.10591

A. H. Gomaa, "LSS 4.0: A conceptual framework for integrating Lean Six Sigma and Industry 4.0 for smart manufacturing excellence," Indian J. Manag. Lang., vol. 5, no. 1, pp. 8–9, Apr. 2025. doi: https://doi.org/10.54105/ijml.H1810.05010425.

M. Zia-ur-Rehman, M. Hashim, H. U. Rehman, and A. Khan, "Enablers and barriers for adoption of Lean system: A mix method approach," Int. J. Product. Qual. Manag., vol. 35, no. 2, pp. 220–240, Mar. 2022.

Copyright (c) 2025 Muhammad Zaid Khan, Ali Zulqarnain, Muhammad Wasif, Rabiya Siddiqui

This work is licensed under a Creative Commons Attribution 4.0 International License.

This work is licensed under a Creative Commons Attribution 4.0 International License. Authors retain copyright and grant the journal right of first publication with the work simultaneously licensed under a Creative Commons Attribution (CC-BY) 4.0 License that allows others to share the work with an acknowledgement of the work’s authorship and initial publication in this journal.