Process Optimization for the Production of Chitosan Nanofibers via Electrospinning

Abstract

Abstract Views: 0

Abstract Views: 0

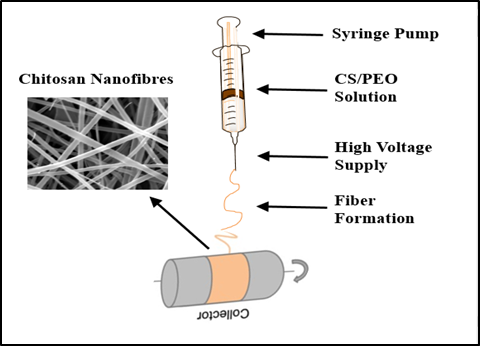

Chitosan (CS) is an important biomaterial recognized for its wide-ranging applications in filtration, wound dressings, tissue engineering, and as a natural antimicrobial agent. The incorporation of nanofibers significantly enhances the filtration performance of materials by increasing surface area. Chitosan-derived nanofibers can also impart antibacterial properties to the resulting nanocomposite filter material. Consequently, the electrospinning process was optimized to produce chitosan nanofibers at the highest feasible concentration for filtration applications. Polyethylene oxide (PEO) was utilized as a co-spinning agent, while glacial acetic acid (50%) served as the solvent during the electrospinning process. Surface morphology and fiber diameter were assessed using scanning electron microscopy (SEM). The findings indicated that smooth nanofibers were

successfully produced from solutions containing 1% to 3.5% chitosan. However, at concentrations of 4% or higher, the production of nanofibers was impeded due to increased viscosity and surface tension of the solution.

Additionally, analysis of fiber diameter revealed that higher applied voltage and greater working distance led to the formation of finer nanofibers. In conclusion, the nanofibers produced at the maximum viable concentration

of chitosan demonstrate significant potential for antibacterial filtration and biomedical applications.

Downloads

References

D. J. Lockwood, “Overview of the electrospinning,” in Electrospun Nanofibers for Energy and Environmental Applications, B. Ding and J. Yu, Eds., Springer-Verlag Berlin, 2014.

D. J. Lockwood, “Basic principles,” in Electrospun Nanofibers for Energy and Environmental Applications, B. Ding and J. Yu, Eds., Springer-Verlag Berlin, 2014.

X. Geng, O. H. Kwon, and J. Jang, “Electrospinning of chitosan dissolved in concentrated acetic acid solution,” Biomaterials, vol. 26, no. 27, pp. 5427–5432, Sep. 2005, doi: https://doi.org/ 10.1016/j.biomaterials.2005.01.066.

H. Homayoni, S. A. H. Ravandi, and M. Valizadeh, “Electrospinning of chitosan nanofibers: Processing optimization,” Carbohydr. Polym., vol. 77, no. 3, pp. 656–661, July 2009, doi: https://doi.org/ 10.1016/j.carbpol.2009.02.008.

M. Cao, F. Gu, C. Rao, J. Fu, and P. Zhao, “Improving the electrospinning process of fabricating nanofibrous membranes to filter PM2.5,” Sci. Total Environ., vol. 666, pp. 1011–1021, May 2019, doi: https://doi.org/10.1016/j.scitotenv.2019.02.207.

S. H. Ali, M. A. Mahammed, and S. A. Yasin, “Characterization of electrospinning chitosan nanofibers used for wound dressing,” Polymers, vol. 16, no. 14, Art no. 1984, July 2024, doi: https://doi.org/10.3390/polym16141984.

G. R. C. Cerqueira et al., “Development of PVA/chitosan nanofibers by a green route using solution blow spinning,” J. Polym. Environ., vol. 32, no. 3, pp. 1489–1499, Mar. 2024, doi: https://doi.org/ 10.1007/s10924-023-03033-3.

V. Kadam, I. L. Kyratzis, Y. B. Truong, J. Schutz, and L. Wang, “2019 Electrospun bilayer nanomembrane with hierarchical placement of bead-on-string and fibers for low resistance respiratory air filtration.pdf,” Sep. Purif. Technol., vol. 224, no. 1, pp. 247–254, Oct. 2019, doi: https://doi.org/10.1016/j.seppur.2019.05.033.

M. Liu, X. P. Duan, Y. M. Li, D. P. Yang, and Y. Z. Long, “Electrospun nanofibers for wound healing,” Mater. Sci. Eng. C, vol. 76, pp. 1413–1423, July 2017, doi: https://doi.org/10.1016/j.msec. 2017.03.034.

K. Sun and Z. H. Li, “Preparations, properties and applications of chitosan based nanofibers fabricated by electrospinning,” Exp. Polym. Lett., vol. 5, no. 4, pp. 342–361, 2011, doi: https://doi.org/10.3144 /expresspolymlett.2011.34.

U. Habiba et al., “Effect of deacetylation on property of electrospun chitosan/PVA nanofibrous membrane and removal of methyl orange, FE(III) nad Cr(VI) ions.pdf,” Carbohydr. Polym., vol. 177, pp. 32–39, Dec. 2017, doi: https://doi.org/10.1016/j.carbpol.2017.08.115

K. Kurita, “Chitin and chitosan: Functional biopolymers from marine crustaceans,” Marine Biotechnol., vol. 8, no. 3, pp. 203–226, Mar. 2006, doi: https://doi.org/10.1007/s10126-005-0097-5.

P. B. Malafaya, G. A. Silva, and R. L. Reis, “Natural-origin polymers as carriers and scaffolds for biomolecules and cell delivery in tissue engineering applications,” Adv. Drug. Deliv. Rev., vol. 59, no. 4–5, pp. 207–233, May 2007, doi: https://doi.org/10.1016/ j.addr.2007.03.012.

T. V Shakola et al., “The first electrochemical N- arylation of chitosan. Antibacterial effect of novel cationic chitosan derivatives,” Eur. Polym. J., vol. 198, Art. no. 112418, Oct. 2023, doi: https://doi.org/10.1016/j.eurpolymj.2023.112418.

K. M. Vårum, M. M. Myhr, R. J. N. Hjerde, and O. Smidsrød, “In vitro degradation rates of partially N-acetylated chitosans in human serum,” Carbohydr. Res., vol. 299, no. 1–2, pp. 99–101, Mar. 1997, doi: https://doi.org/10.1016/S0008-6215(96)00332-1.

P. J. VandeVord, H. W. T. Matthew, S. P. DeSilva, L. Mayton, B. Wu, and P. H. Wooley, “Evaluation of the biocompatibility of a chitosan scaffold in mice,” J. Biomed. Mater. Res., vol. 59, no. 3, pp. 585–590, 2002, doi: https://doi.org/10.1002/jbm.1270.

K. Piekarska, M. Sikora, M. Wi, and M. Owczarek, “Chitin and chitosan as polymers of the future — Obtaining, modification, life cycle assessment and main directions of application,” Polymers, vol. 15, no. 4, Art. no. 793, 2023, doi: https://doi.org/ 10.3390/polym15040793.

Z. Liu, K. Wang, X. Peng, and L. Zhang, “Chitosan-based drug delivery systems: Current strategic design and potential application in human hard tissue repair,” Eur. Polym. J., vol. 166, no. 14, Art. no. 110979, Mar. 2022, doi: https://doi.org/10.1016/j. eurpolymj.2021.110979.

X. Dong et al., “Chitin/Chitosan nanofibers toward a sustainable future: From hierarchical structural regulation to functionalization applications,” Nano. Lett., vol. 24, no. 39, pp. 12014–12026, Oct. 2024, doi: https://doi.org/10.1021/acs.nanolett.4c02632.

M. T. Khawar, H. Gong, Q. Zia, H. H. Nawaz, and J. Li, “Chitosan nanofibres and polypropylene meltblown substrate based multilayer respiratory filter for byssinosis prevention,” J. Indust. Text., vol. 52, p. 1–6, 2022, doi: https://doi.org/10.1177/15280837221111173.

E. I. Rabea, M. E.-T. Badawy, C. V. Stevens, G. Smagghe, and W. Steurbaut, “Chitosan as antimicrobial agent: Applications and mode of action chitosan as antimicrobial agent: Applications and mode of action,” Biomacromolecules, vol. 4, no. 6, pp. 1457–1465, Sep. 20023, doi: https://doi.org/10.1021/bm034130m

H. Sashiwa and S. I. Aiba, “Chemically modified chitin and chitosan as biomaterials,” Prog. Poly. Sci., vol. 29, no. 9, pp. 887–908, Sep. 2004, doi: https://doi.org/10.1016/j.progpolymsci.2004.04.001.

E. A. El-hefian, M. M. Nasef, and A. H. Yahaya, “Chitosan physical forms: A short review,” Aust. J. Basic. Appl. Sci., vol. 5, no. 5, pp. 670–677, 2011.

Q. Zia et al., “Porous poly (L–lactic acid)/chitosan nanofibres for copper ion adsorption,” Carbohydr. Polym., vol. 227, Art. no. 115343, Jan. 2020, doi: https://doi.org/10.1016/j.carbpol.2019.115343.

A. Cooper, R. Oldinski, H. Ma, J. D. Bryers, and M. Zhang, “Chitosan-based nanofibrous membranes for antibacterial filter applications,” Carbohydr. Polym., vol. 92, no. 1, pp. 254–259, 2013, doi: https://doi.org/10.1016/j.carbpol.2012.08.114.

S. M. Lemma, F. Bossard, and M. Rinaudo, “Preparation of pure and stable chitosan nanofibers by electrospinning in the presence of poly (ethylene oxide),” Int. J. Mol. Sci., vol. 17, no. 11, Art. no. 1790, Oct. 2016, doi: https://doi.org/10.3390/ijms17111790.

K. Liu et al., “Concurrent filtration and inactivation of bacteria using poly (vinyl alcohol-co-ethylene) nanofibrous membrane facilely modified using chitosan and graphene oxide,” Environ. Sci. Nano., vol. 4, no. 2, pp. 385–395, 2017, doi: https://doi.org/10.1039/c6en00364h.

J. Xue, T. Wu, Y. Dai, and Y. Xia, “Electrospinning and electrospun nanofibers: Methods, materials, and applications,” Chem. Rev., vol. 119, no. 8, pp. 5298–5415, 2019, doi: https://doi.org/10. 1021/acs.chemrev.8b00593.

J. Hu, X. Wang, B. Ding, J. Lin, J. Yu, and G. Sun, “One-step electro-spinning/netting technique for controllably preparing polyurethane nano-fiber/net,” Macromol. Rapid. Commun., vol. 32, no. 21, pp. 1729–1734, Aug. 2011, doi: https://doi.org/10. 1002/marc.201100343.

Copyright (c) 2025 Dr. Muhammad Tauseef Khawar, Dr. Wasif Razzaq, Dr. Amjad Farooq, Dr. Zakariya Zubair

This work is licensed under a Creative Commons Attribution 4.0 International License.

This work is licensed under a Creative Commons Attribution 4.0 International License. Authors retain copyright and grant the journal right of first publication with the work simultaneously licensed under a Creative Commons Attribution (CC-BY) 4.0 License that allows others to share the work with an acknowledgement of the work’s authorship and initial publication in this journal.