Isolation of Keratinolytic Bacteria from Common Ostrich (Struthio Camelus) and their Efficacy towards Feather Degradation of Poultry Waste

Abstract

Abstract Views: 189

Abstract Views: 189

Keratinolytic microorganisms have the capacity to biosynthesize particular keratinases and determine their

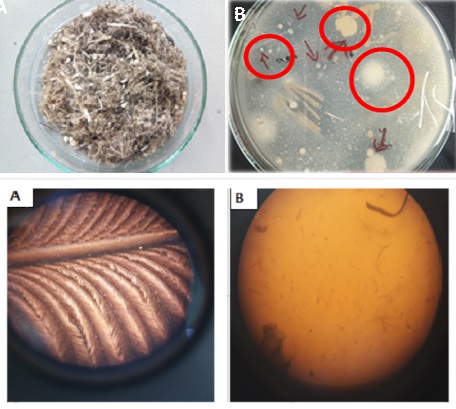

prospective application in poultry waste management. Hence, the objective of this study was to utilize keratinolytic microbes for the degradation of poultry waste. For this purpose, the feathers of common ostrich (Struthio camelus) were collected, scattered along the surrounding dry soil, from a private ostrich farm in Kasur, Pakistan. Bacteria were isolated by using culture enrichment techniques and screened for their proteolytic activity on skim milk agar. The isolates were characterized clonially, morphologically, and biochemically and labeled as SNO1, SNO2, and SNO3, respectively. The effects of varied pH and temperatures were recorded on bacterial growth and feather degradation. It was noticed that the bacterial cell densities and feather degradation were high at 50˚C and pH 8.0, as compared to the rest of the culture conditions. Visual observations were made using a stereomicroscope. The maximum feather degradation in the form of white powdery mass was noticed at fourth (4 th ) week. The protein content of Struthio camelus feathers was determined as 6.5 mg/100 ml after degradation. Taken together, the authors concluded that the isolated strains were capable of feather degradation and can be used in poultry waste management.

Downloads

References

Moreki JC, Keaikitse T. Poultry waste management practices in selected poultry operations around Gaborone, Botswana. Int J Curr Microbiol App Sci. 2013;2(7):240-248.

Li F, Cheng S, Yu H, Yang D. Waste from livestock and poultry breeding and its potential assessment of biogas energy in rural China. J Clean Prod. 2016;126:451-460. https://doi.org/10.1016/j.jclepro.2016.02.104

Kraham SJ. Environmental impacts of industrial livestock production. In: Steier G, Patel K, eds. International farm animal, wildlife and food safety law. Springer, Cham; 2017. https://doi.org/10.1007/978-3-319-18002-1_1

Cooper RG. Ostrich database in Africa. Paper presented at: XIV world ostrich congress; Riga, Latvia.

Cooper RG, Mahrose K, Horbańczuk JO, Villegas-Vizcaíno R, Kennou Sebei S, Faki Mohammed A E. The wild ostrich (Struthio camelus): A review. Trop Anim Health Prod. 2009;41(8):1669-1678. https://doi.org/10.1007/s11250-009-9364-1

Magige F, Røskaft E. Medicinal and commercial uses of ostrich products in Tanzania. J Ethnobiol Ethnomed. 2017;13(1):1-7. https://doi.org/10.1186/s13002-017-0176-5

Abbas G, Qureshi CMUR, Asif M, Sajid M, Zahid SWAO, Saeed H. Ostrich industry: A beautiful u turn in poultry industry of Pakistan. Int J Ani Husb Vet Sci. 2018;3(1):2455-8567.

Abbas G, Zahid O, Khan MSA, Sajid M, Saeed H. Future of ostrich farming in Pakistan. Adv Zoo Bot. 2018;6(2):55-65.

Tesfaye T, Sithole B, Ramjugernath D. Valorisation of chicken feathers: A review on recycling and recovery route—current status and future prospects. Clean Techn Environ Policy. 2017;19(10):2363-2378. https://doi.org/10.1007/s10098-017-1443-9

Godbole S, Pattan J, Gaikwad S, Jha T. Isolation, identification and characterization of keratin degrading microorganisms from poultry soil and their feather degradation potential. Int J Environ Agri Biot. 2017;2(4): e238876.

Kumar M, Kumar R, Malik DK. Keratin degradation by bacterial strain isolated from poultry farm soil. J Phar Res. 2016;10(2):113-115.

Laba W, Choinska A, Rodziewicz A, Piegza M. Keratinolytic abilities of Micrococcus luteus from poultry waste. Braz J Microbiol. 2015;46(3):691-700.

Riffel A, Lucas F, Heeb P, Brandelli A. Characterization of a new keratinolytic bacterium that completely degrades native feather keratin. Archiv Microbiol. 2003;179(4):258-265.

Gurav RG, Jadhav JP. A novel source of biofertilizer from feather biomass for banana cultivation. Environ Sci Pollu Res. 2013;20(7):4532-4539. https://doi.org/10.1007/s11356-012-1405-z

Singh S, Masih H. Isolation of keratinolytic bacteria from soil for the bioconversion of the poultry feather waste. J Pure Appl Microbiol. 2015;9(3):2281-2285.

Hudon J. Considerations in the conservation of feathers and hair, particularly their pigments. Paper presented in: CAC/ACCR 31st Annual Conference, Jasper; 2005.

Laba W, Rodziewicz A. Biodegradation of hard keratins by two Bacillus strains. Jundishapur J Microbiol. 2014;7(2):e8896. https://doi.org/10.5812/jjm.8896

He Z, Sun R, Tang Z, et al. Biodegradation of feather waste keratin by a keratin-degrading strain of Bacillus subtilis 8. J Microbiol Biot. 2018;28(2):314-322. https://doi.org/10.4014/jmb.1708.08077

Zaghloul TI. Cloned Bacillus subtilis alkaline protease (aprA) gene showing high level of keratinolytic activity. Paper presented in: Proceedings of the Nineteenth Symposium on Biotechnology for Fuels and Chemicals Held, Colorado Springs; 1998.

Cappuccino JG, Sherman N. Techniques for isolation of pure cultures. Pearson Education; 2002

Agrahari S, Wadhwa N. Degradation of chicken feather a poultry waste product by keratinolytic bacteria isolated from dumping site at Ghazipur poultry processing plant. Int J Poult Sci. 2016;9(5):482-489.

Lowry OH, Rosebrough NJ, Farr AL, Randall RJ. Protein measurement with the Folin phenol reagent. J Biol Che. 1951;193(1):265-275.

Lange L, Huang Y, Busk PK. Microbial decomposition of keratin in nature—a new hypothesis of industrial relevance. App Microbiol Biot. 2016;100(5):2083-2096. https://doi.org/10.1007/s00253-015-7262-1

Veenayohini K, Sangeetha D. Isolation and identification of keratinolytic bacteria from poultry waste and assessment of its keratinase activity on chicken feathers. Int J Appl Res. 2016;2(11):396-402.

Ichida JM, Krizova L, LeFevre CA, Keener HM, Elwell DL, Burtt EH, Jr. Bacterial inoculum enhances keratin degradation and biofilm formation in poultry compost. J Microbiol Meth. 2001;47(2):199-208. https://doi.org/10.1016/S0167-7012(01)00302-5

Cai C, Zheng X. Medium optimization for keratinase production in hair substrate by a new Bacillus subtilis KD-N2 using response surface methodology. J Ind Microbiol biot. 2009;36(7):875-883. https://doi.org/10.1007/s10295-009-0565-4

Goldstein G, Flory KR, Browne BA, Majid S, Ichida JM, Burtt JEH. Bacterial degradation of black and white feathers. The Auk. 2004;121(3):656-659. https://doi.org/10.1093/auk/121.3.656

Anbu P, Hilda A, Sur HW, Hur BK, Jayanthi S. Extracellular keratinase from Trichophyton sp. HA-2 isolated from feather dumping soil. Int Biodeter Biodegr. 2008;62(3):287-292. https://doi.org/10.1016/j.ibiod.2007.07.017

Tiwary E, Gupta R, Medium optimization for a novel 58 kDadimerickeratinase from Bacillus licheniformis ER-15: Biochemical characterization and application in feather degradation and dehairing of hides. Bioresour Technol. 2010;101(15);6103-6110. https://doi.org/10.1016/j.biortech.2010.02.090

Daroit DJ, Corrêa APF, Brandelli A. Production of keratinolytic proteases through bioconversion of feather meal by the Amazonian bacterium Bacillus sp. P45. Int Biodeter Biodegr. 2011;65(1):45-51. https://doi.org/10.1016/j.ibiod.2010.04.014

Uttangi V, Aruna K. Optimization of production and partial characterization of Keratinase produced by Bacillus thuringiensis strain Bt407 Isolated from Poultry Soil. Int J Curr Microbiol App Sci. 2018;7(4):596-626

Yue X, Zhang B, Zou J, Chen W, Yang N. Characterization of a new bacterium with high alkaline keratinase activity from Calotesversicolor feces. J Biotech Research. 2017;8:83-92.

Ni H, Chen QH, Chen F, Fu ML, Dong YC, Cai HN. Improved keratinase production for feather degradation by Bacillus licheniformis ZJUEL31410 in submerged cultivation. Afr J Biotechnol. 2011;10(37):7236-7244.

Yamamura S, Morita Y, Hasan Q, Yokoyama K, Tamiya E. Keratin degradation: A cooperative action of two enzymes from Stenotrophomonas sp. Biochem Biophysic Res Comm. 2002;294(5):1138-1143. https://doi.org/10.1016/S0006-291X(02)00580-6

Poovendran P, Kalaigandhi V, Kanan VK, Poongunran E. A study of feather keratin degradation by Bacillus licheniformis and quantification of keratinase enzyme produced. J Microbiol Biotechnol. 2017;1(3):120-126.

Copyright (c) 2022 Uzma Rafi, Aisha Waheed Qureshi, Roheela Yasmeen Yasmeen, Sahar Noor, Syeda Shazia Bokhari

This work is licensed under a Creative Commons Attribution 4.0 International License.

BSR follows an open-access publishing policy and full text of all published articles is available free, immediately upon publication of an issue. The journal’s contents are published and distributed under the terms of the Creative Commons Attribution 4.0 International (CC-BY 4.0) license. Thus, the work submitted to the journal implies that it is original, unpublished work of the authors (neither published previously nor accepted/under consideration for publication elsewhere). On acceptance of a manuscript for publication, a corresponding author on the behalf of all co-authors of the manuscript will sign and submit a completed the Copyright and Author Consent Form.