A Comprehensive Review on Supplementary Cementitious Materials – Progress, Environmental Impact, and Future Sustainability Challenges

Abstract

Abstract Views: 0

Abstract Views: 0

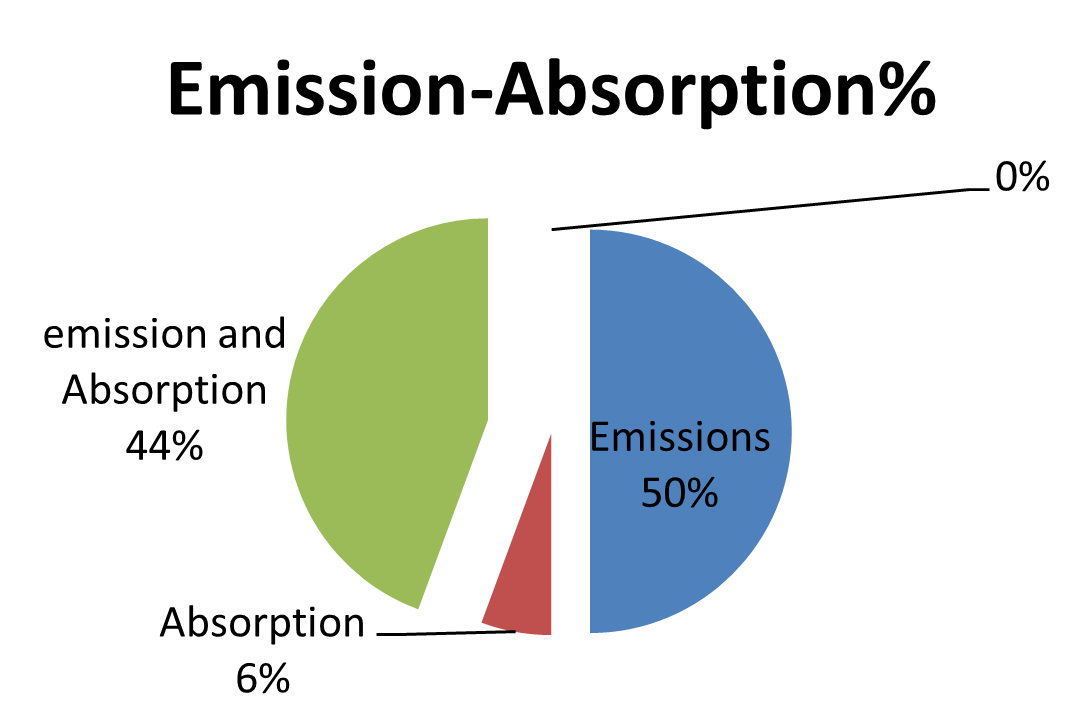

High-performance concrete involves the use of massive quantities of Portland cement and other Supplementary Cementitious Materials (SCMs), which add to its performance and sustainability. In this paper, the researcher examines the impacts of various SCMs on concrete and concludes that, the use of these materials with cement enhances compressive and mechanical strength. Ordinary SCMs are metakaolin, blast furnace slag, silica fume, laterite, fly ash, rice husk ash, nano-materials, blended cement, and sugarcane bagasse ash. In fresh concrete, SCMs affect the mechanical properties, which include elastic modulus development, strain of shrinkage, compressive strength, and flexural strength. The use of traditional SCMs, such as BFS and fly ash, has up until now been in use over decades and the effects of the SCMs on cement hydration and concrete performance are well documented. SCMs are important constituents of cementitious systems and the replacement of the ordinary Portland cement partially by them is a popular industrial practice. The application of SCMs also leads to the sustainability of the environment through decreased CO2 emissions. Carbon footprint can be reduced to a considerable extent by using partially replaced Portland cement with environmentally-friendly powders (fly ash, slag, rice husk ash, or metakaolin). The cement production is a highly energy-consuming process which emits high levels of CO2 throughout the process of limestone calcination, thus the integration of SCMs can help to save energy and minimize the emissions of greenhouse gases. Other than environmental advantages, SCMs enhance the durability of concrete, its strength and its resistance to chemical attack by refining its microstructure with the reaction of pozzolans. In general, the research on SCMs sums up their availability, influence on cement performance and durability, environmental impacts, and challenges of the construction sector and all points to the movement toward more sustainable concrete production

Downloads

References

Abdel-Rahman HA, Younes MM. Performance of irradiated blended cement paste composites containing ceramic waste powder towards sulfates, chlorides, and seawater attack. J Vinyl Addit Technol. 2020;26(1):24-34. https://doi.org/10.1002/vnl.21743

Proença JD, Suzuki MM, Costa SC, Hirata BS, Lopes MB, Contreras EF. Influence of different water types on the physical and mechanical properties of gypsum. Braz J Oral Sci. 2015;14(3):199-203. https://doi.org/10.1590/1677-3225v14n3a05

Beaudoin J, Odler I. Hydration, setting and hardening. In: Lea’s Chemistry of Cement and Concrete. 5th ed. Elsevier; 2019:157.

Gartner E, Sui T. Alternative cement clinkers. Cem Concr Res. 2018;114:27-39. https://doi.org/10.1016/j.cemconres.2018.04.007

Li Y, Liu ZY, Jiang JY, et al. Microstructure and macroscopic properties of low-carbon concrete subjected to elevated temperature: state-of-the-art review. J Build Eng. 2024;86:e108731. https://doi.org/10.1016/j.jobe.2024.108731

Imbabi MS, Carrigan C, McKenna S. Trends and developments in green cement and concrete technology. Int J Sustain Built Environ. 2012;1(2):194-216. https://doi.org/10.1016/j.ijsbe.2013.05.001

Dan AK, Bhattacharjee D, Ghosh S, et al. Prospective utilization of coal fly ash for making advanced materials. In: Clean Coal Technologies. Springer; 2021:511-531.

Ahmad J, Kontoleon KJ, Majdi A, et al. A comprehensive review on ground granulated blast furnace slag in concrete production. Sustainability. 2022;14(14):8783. https://doi.org/10.3390/su14148783

Marjanović N, Komljenović M, Baščarević Z, Nikolić V, Petrović R. Physical–mechanical and microstructural properties of alkali-activated fly ash–blast furnace slag blends. Ceram Int. 2015;41(1):1421-1435. https://doi.org/10.1016/j.ceramint.2014.09.075

Babu KG, Prakash PS. Efficiency of silica fume in concrete. Cem Concr Res. 1995;25(6):1273-1283. https://doi.org/10.1016/0008-8846(95)00119-1

Badogiannis E, Kakali G, Tsivilis S. Metakaolin as supplementary cementitious material: optimization of kaolin to metakaolin conversion. J Therm Anal Calorim. 2005;81(2):457-462. https://doi.org/10.1007/s10973-005-0975-2

Bahurudeen A, Kanraj D, Dev VG, Santhanam M. Performance evaluation of sugarcane bagasse ash blended cement in concrete. Cem Concr Compos. 2015;59:77-88. https://doi.org/10.1016/j.cemconcomp.2015.03.004

Bautista-Gutierrez KP, Herrera-May AL, Santamaría-López JM, Honorato-Moreno A, Zamora-Castro SA. Recent progress in nanomaterials for modern concrete infrastructure. Materials. 2019;12(21):e3548. https://doi.org/10.3390/ma12213548

Bhanja S, Sengupta B. Investigations on the compressive strength of silica fume concrete using statistical methods. Cem Concr Res. 2002;32(9):1391-1394. https://doi.org/10.1016/S0008-8846(02)00828-4

Bhanja S, Sengupta B. Influence of silica fume on the tensile strength of concrete. Cem Concr Res. 2005;35(4):743-747. https://doi.org/10.1016/j.cemconres.2004.05.024

Boscaro F, Palacios M, Flatt RJ. Formulation of low clinker blended cements and concrete with enhanced fresh and hardened properties. Cem Concr Res. 2021;150:e106605. https://doi.org/10.1016/j.cemconres.2021.106605

Bredy P, Chabannet M, Pera J. Microstructure and porosity of metakaolin blended cements. MRS Online Proc Libr. 1988;136:275-280. https://doi.org/10.1557/PROC-136-275

Brown ET, Bourlès DL, Colin F, et al. Development of iron crust lateritic systems in Burkina Faso. Earth Planet Sci Lett. 1994;124(1-4):19-33. https://doi.org/10.1016/0012-821X(94)00066-X

Buenfeld NR, Newman JB. The permeability of concrete in a marine environment. Mag Concr Res. 1984;36(127):67-80. https://doi.org/10.1680/macr.1984.36.127.67

Bukhari SA, Chaudhry AH, Iqbal MN, Siddiqui RH. Performance of cement containing laterite as supplementary cementing material. J Chem Chem Eng. 2013;62(3):65-70.

Cadrin SX, Karr LA, Mariani S. Stock identification methods: an overview. In: Stock Identification Methods. Elsevier; 2014:1-5. https://doi.org/10.1016/B978-0-12-397003-9.00001-5

Çakır Ö. Experimental analysis of recycled coarse aggregate concrete with mineral additives. Constr Build Mater. 2014;68:17-25. https://doi.org/10.1016/j.conbuildmat.2014.06.032

Calvin WD. Thermal drying: turning bagasse from a problem to a profit center. IPPTA. 1996;8:61-68.

Camargo-Pérez NR, Abellán-García J, Fuentes L. Rice husk ash as supplementary cementitious material for pavements. J Mater Res Technol. 2023;25:6167-6182. https://doi.org/10.1016/j.jmrt.2023.03.260

Cid-Falceto J, Mazarrón FR, Cañas I. Assessment of compressed earth blocks made in Spain. Constr Build Mater. 2012;37:738-745. https://doi.org/10.1016/j.conbuildmat.2012.04.013

Cordeiro GC, Toledo Filho RD, Tavares LM, Fairbairn EMR. Binary and ternary blended cement concretes with agro-ashes. Constr Build Mater. 2012;29:641-646. https://doi.org/10.1016/j.conbuildmat.2011.07.029

Bjegovic D, Stirmer N, Serdar M. Durability of concrete improved by extremely fine cementitious materials. Mater Corros. 2012;63(12):1087-1096. https://doi.org/10.1002/maco.201206664

de Sande VT, Sadique M, Pineda P, et al. Sugar cane bagasse ash as sand replacement. J Build Eng. 2021;39:e102277. https://doi.org/10.1016/j.jobe.2021.102277

Diamond SA, Kennedy AJ, Melby NL, et al. Potential hazard of nanoscale TiO₂ in photocatalytic cement. NanoImpact. 2017;8:11-19. https://doi.org/10.1016/j.impact.2017.06.001

Dimoudi A, Tompa C. Energy and environmental indicators of office buildings. Resour Conserv Recycl. 2008;53(1-2):86-95. https://doi.org/10.1016/j.resconrec.2008.09.008

Farabi H, Ramroop I. Bagasse: controlling pollution from a free fuel. Chem Eng World. 1994;29(3):51-56.

Galán-Marín C, Rivera-Gómez C, Petric J. Clay-based composites stabilized with natural polymer. Constr Build Mater. 2010;24(8):1462-1468. https://doi.org/10.1016/j.conbuildmat.2010.01.008

Ganesan K, Rajagopal K, Thangavel K. Evaluation of bagasse ash as supplementary cementitious material. Cem Concr Compos. 2007;29(6):515-524. https://doi.org/10.1016/j.cemconcomp.2007.03.001

Goel G, Sachdeva P, Chaudhary AK, Singh Y. Nanomaterials in concrete: a review. Mater Today Proc. 2022;69:365-371. https://doi.org/10.1016/j.matpr.2022.01.060

Goldman A, Bentur A. Influence of microfillers on concrete strength. Cem Concr Res. 1993;23(4):962-972. https://doi.org/10.1016/0008-8846(93)90161-J

Gopalan MK. Sorptivity of fly ash concretes. Cem Concr Res. 1996;26(8):1189-1197. https://doi.org/10.1016/0008-8846(96)00114-1

Hall C. Water movement in porous building materials—IV. Build Environ. 1981;16(3):201-207. https://doi.org/10.1016/0360-1323(81)90023-2

Hall C. Water sorptivity of mortars and concretes. Mag Concr Res. 1989;41(147):51-61. https://doi.org/10.1680/macr.1989.41.147.51

Halstead WJ. Use of fly ash in concrete. NCHRP Synth Highw Pract. 1986;(127):1-45.

Ho DS, Lewis RK. Water sorptivity of concretes under continuous curing. Durab Build Mater. 1987;4(3):241-252. https://doi.org/10.1016/0167-3890(87)90015-8

Hussien NT, Oan AF. Use of sugarcane wastes in concrete. J Eng Appl Sci. 2022;69(1):e31. https://doi.org/10.1186/s44147-022-00051-w

Indukuri CSR, Nerella R, Madduru SRC. Effect of graphene oxide on cement composites. Constr Build Mater. 2019;229:e116863. https://doi.org/10.1016/j.conbuildmat.2019.116863

John N. Strength properties of metakaolin admixed concrete. Int J Sci Res Publ. 2013;3(6):1-7.

Justice JM, Kurtis KE. Influence of metakaolin surface area. J Mater Civ Eng. 2007;19(9):762-771. https://doi.org/10.1061/(ASCE)0899-1561(2007)19:9(762)

Jose A, Kasthurba AK. Laterite soil-cement blocks modified with natural rubber latex. Constr Build Mater. 2021;273:e121991. https://doi.org/10.1016/j.conbuildmat.2020.121991

Kaze CR, Lecomte-Nana GL, Kamseu E, et al. Inorganic polymer cement from laterite. Cem Concr Res. 2021;140:e106320. https://doi.org/10.1016/j.cemconres.2020.106320

Kaze RC, Moungam LB, Djouka MF, et al. Corrosion of kaolinite and geopolymerization. Appl Clay Sci. 2017;138:48-62. https://doi.org/10.1016/j.clay.2016.12.020

Kazemi R, Gholampour A. Rapid chloride permeability using AI. Constr Build Mater. 2023;409:e133835. https://doi.org/10.1016/j.conbuildmat.2023.133835

Kelham S. Water absorption test for concrete. Mag Concr Res. 1988;40(143):106-110. https://doi.org/10.1680/macr.1988.40.143.106

Khalil MJ, Aslam M, Ahmad S. Sugarcane bagasse ash as cement replacement. Constr Build Mater. 2021;270:e121371. https://doi.org/10.1016/j.conbuildmat.2020.121371

Copyright (c) 2025 Nimra Iqbal, Shaukat Ali, Maria Ajmal, Nimra, Nosheen Sial, Asif Hanif Chaudhry, Muhammad Aslam

This work is licensed under a Creative Commons Attribution 4.0 International License.